SLUSBZ6A April 2016 – August 2016 TPS92515 , TPS92515-Q1 , TPS92515HV , TPS92515HV-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 General Operation

- 8.3.2 Current Sense Comparator

- 8.3.3 OFF Timer

- 8.3.4 OFF-Timer, Shunt FET Dimming or Shunted Output Condition

- 8.3.5 Internal N-channel MOSFET

- 8.3.6 VCC Internal Regulator and Undervoltage Lockout (UVLO)

- 8.3.7 Analog Adjust Input

- 8.3.8 Thermal Protection

- 8.3.9 Junction Temperature Relative Estimation

- 8.3.10 BOOT and BOOT UVLO

- 8.3.11 PWM (UVLO and Enable)

- 8.4 Device Functional Modes

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Application

- 9.2.1 General Design Procedure

- 9.2.2 Design Requirements

- 9.2.3

Detailed Design Procedure

- 9.2.3.1 Calculating Duty Cycle

- 9.2.3.2 Calculate OFF-Time Estimate

- 9.2.3.3 Calculate OFF-Time Resistor ROFF

- 9.2.3.4 Calculate the Inductance Value

- 9.2.3.5 Calculate the Sense Resistance

- 9.2.3.6 Calculate Input Capacitance

- 9.2.3.7 Verify Peak Current for Inductor Selection

- 9.2.3.8 Calculate Output Capacitance

- 9.2.3.9 Calculate UVLO Resistance Values

- 9.2.4 Application Curves

- 9.3 Dos and Don'ts

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

9.2.4 Application Curves

Buck LED driver example: VOUT = 22 V (7 LEDs), IOUT = 1 A

| VLED = 22 V | IOUT = 1.0 A |

A. Ch1: SW Voltage; Ch2: VIN (DC Coupled);

Ch4: Inductor current; UVLO designed limit attained.

Time: 1 ms/div

Figure 36. Startup Transient Ch4: Inductor current; UVLO designed limit attained.

Time: 1 ms/div

A. Ch1: SW Voltage; Ch2: VIN (DC Coupled);

Ch4: Inductor current;

Time: 8 µs/div

Figure 38. First 15 SW Node Pulses at Turn-On Ch4: Inductor current;

Time: 8 µs/div

A. Ch1: SW Voltage; Ch2: PWM pin;

Ch4: Inductor current;

Time: 10 µs/div

Figure 40. PWM Dimming: 250Hz, 1% Duty Cycle Ch4: Inductor current;

Time: 10 µs/div

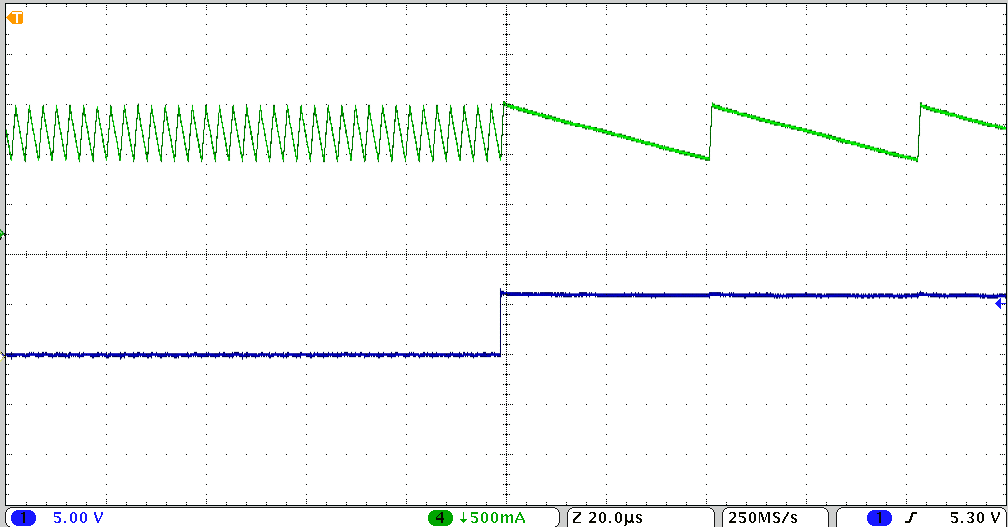

A. Ch1: PWM Signal

Ch4: Inductor current; ΔIL-PP Maintained

Time: 20 µs/div

Figure 42. Shunt FET Dimming - Optimized Inductor Current Waveform Ch4: Inductor current; ΔIL-PP Maintained

Time: 20 µs/div

A. Ch1: SW Voltage; Ch2: VIN Ripple Voltage (AC Coupled);

Ch3: ILED-PP; Ch4: Inductor current;

Time: 1 µs/div

Figure 35. Normal Operation Ch3: ILED-PP; Ch4: Inductor current;

Time: 1 µs/div

A. Ch1: SW Voltage; Ch2: VIN (DC Coupled);

Ch4: Inductor current; UVLO designed limit attained.

Time: 1 ms/div

Figure 37. Shut-Down Transient Ch4: Inductor current; UVLO designed limit attained.

Time: 1 ms/div

A. Ch1: SW Voltage; Ch2: PWM pin;

Ch4: Inductor current;

Time: 10 µs/div

Figure 39. PWM Dimming: 250Hz, 0.25% Duty Cycle Ch4: Inductor current;

Time: 10 µs/div

A. Ch1: SW Voltage; Ch2: PWM pin;

Ch4: Inductor current;

Time: 1 ms/div

Figure 41. PWM Dimming: 250Hz, 50% Duty Cycle Ch4: Inductor current;

Time: 1 ms/div

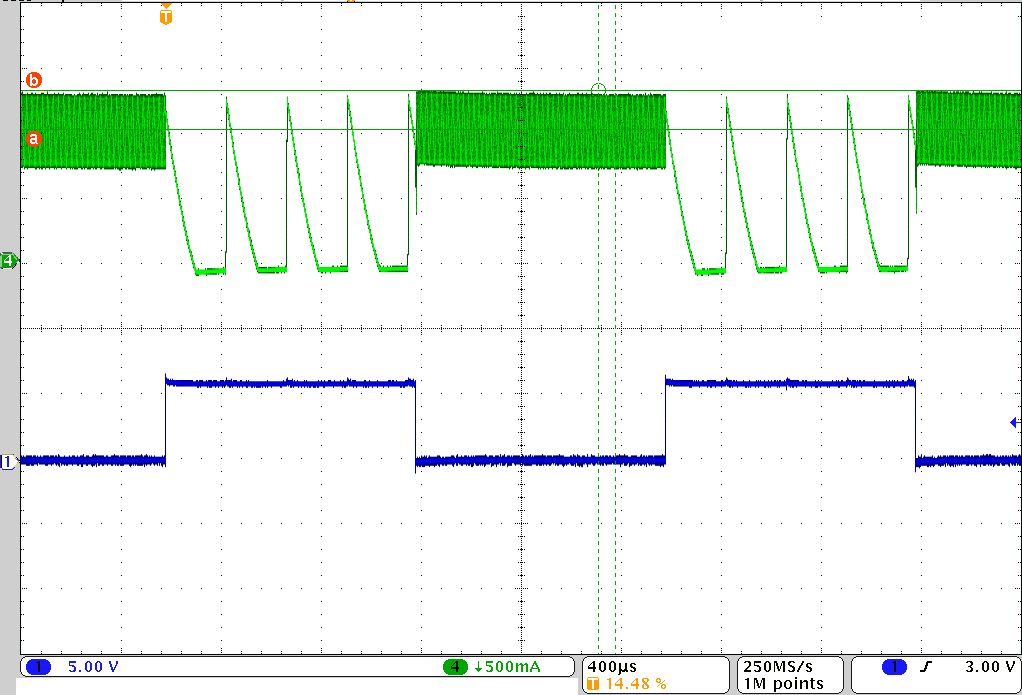

A. Ch1: PWM Signal

Ch4: Inductor current; OFF-time reaching Maximum OFF-Time

Time: 400 µs/div

Figure 43. Shunt FET Dimming - Non-Optimized Inductor Current Ch4: Inductor current; OFF-time reaching Maximum OFF-Time

Time: 400 µs/div